Important Notes

Safety Notes

When selecting or installing the product, be sure to read the Safety Precautions, Catalog, and Instruction Manual before installing the product, as misuse may cause danger. After reading the Instruction Manual, keep it in a place where the user can read it at any time. When transferring or lending the product to another person, place the “Instruction Manual” in a conspicuous place on the product body so that the new owner can understand the proper and safe use of the product. The dangers, warnings, etc. in the Safety Precautions do not cover all possible situations. Please read the product catalog and instruction manual carefully.

Please read the product catalog and instruction manual carefully, and always place safety as your top priority.

. Prohibit uninvolved persons from entering the perimeter of the gun changer disk workplace;

. Do the installation and maintenance check more than 5 minutes after disconnecting all input side power;

. Do not use cables with insufficient capacity, damage, or exposed wires;

. Securely fasten and insulate the connections of cables and connectors;

. Do not use gloves that are damaged or wet, but use dry, insulated gloves;

. Perform regular maintenance and inspection, and repair damaged parts before use.

. If cables, tubes, and pipes have been prepared, use a product that can adequately withstand the air pressure of the specified load;

. When the equipment is not in use, put down the robot end-effector and leave it unattended.

– Do not share the Wanfur’s quick changer “LOCK” air inlet line with other machines or equipment using a tee. Cross-use of the air source will lead to the return of air, affecting the gun changer disk gripping air pressure becomes smaller, and ultimately lead to equipment failure or gun drop;

– When the EVA Quick-Change is not disconnected for a long time and is always connected, the ‘UNLOCK’ port must not be plugged. In addition, air pressure must be continuously applied to the ‘LOCK’ port, otherwise, equipment failure or tool drop may occur;

– The Wanfur’s quick changer is equipped with an air cutoff protection mechanism that prevents the tool side from falling off in the event of an unpredictable drop in air pressure. However, the Wanfur’s quick changer air supply line must be designed so that no compression flows into the UNLOCK end of the piping when the solenoid valve is de-energized;

-The low pressure will lead to insufficient gripping force, and the gun changer disk lock release in place is not reliable, eventually leading to equipment failure or the occurrence of gun drop;

-The exhaust port of the solenoid valve controlling the quick change must not be blocked, otherwise, there is a risk of dropping the tool;

-Do not use a 3-position, 5-way solenoid valve to control the quick change, as the solenoid valve will not hold its position in the event of a loss of power, which could result in a gun drop.

-Pay attention to the polarity of the power supply when connecting and debugging the quick-change to avoid damage to the built-in sensor of the quick-change due to wiring error.

Installation Notes

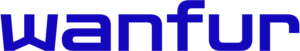

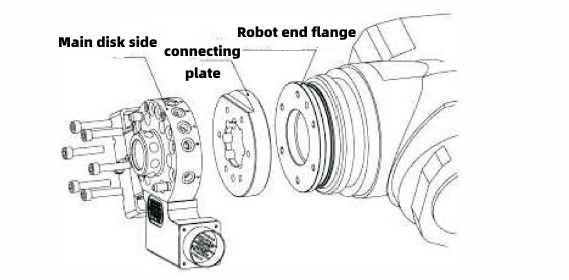

1 Robot mounting: First install the cylindrical pin on the robot flange, and then install the quick-change disk robot side to the robot flange with six 12.9 grade hexagon socket head cap screws, the quick-change disk and the robot are connected by a cylindrical pin and the robot flange center slot positioning.

Cautions

.The Cylindrical pins must be used for positioning;

. Different models of robot flange mounting method is different, if you need to add a connecting plate, it is recommended that the connecting plate material: 6061-T6 aluminum alloy.

2 Tool side mounting: first install 2 cylindrical pins of corresponding specifications, and then use 6 12.9 grade internal, hexagonal cylindrical head screws to mount to the designed tool or gripper connection flange.

Cautions

.The Cylindrical pins must be used for positioning;

. Tool tray installation requires the customer to design the corresponding tool or gripper connecting flange according to our dimension drawing;

. Tool tray side tool mounting flange surface shall not have a raised platform or raised part, the center of the body of the tool tray

The center hole of the tool tray body must not be blocked and must be hollowed out;

. The Tool and tool parking bracket positioning clearance is recommended: 0.25-0.5mm.

Usage Notes:

– The Wanfur’s quick changer needs to use clean, dry, oil-free filtered compressed air, with an impurity diameter of less than $ 25 Pm, water content of 0.6mg / m, and air pressure range of 0.4Mpa – 0.7Mpa.

– The Wanfur’s quick changer for general industrial environments, in the selection of quick-change models to confirm that the load and torque values of the tool within the permissible values, and leave an appropriate margin of safety or contact Hashida for technical support;

-In the process of use of the solenoid valve often to the gas port often needs to be connected to the quick-change lock interface, quick-change long time not switching is recommended to switch once a week to ensure the flexibility of the locking mechanism, place the locking mechanism of the phenomenon of jamming, the quick-change in the absence of gripping the tool needs to be kept in a LOCK state, to reduce the air pressure on the internal structure of the consumption;

– During commissioning or use, avoid misoperation of the control signal and avoid manual control of the solenoid valve switching, otherwise the gun changer disk will fall off the accident;

-When separating or connecting the robot, be sure to relieve pressure on the fluid lines (water and air) to prevent fluid leakage, which may cause damage to the seals on the non-self-sealing fluid passages of the gun changer body and dislodgement of the blowout;

-Under normal conditions, when using the Hashida quick-change to connect and disconnect, the contact surfaces of the main and tool disks should be parallel; failure to maintain parallelism will result in inaccurate connection and unsmooth disconnection.