The Ultimate Guide to Automatic Robot Tool Changers: Revolutionizing Robotics and Manufacturing

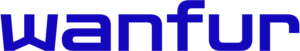

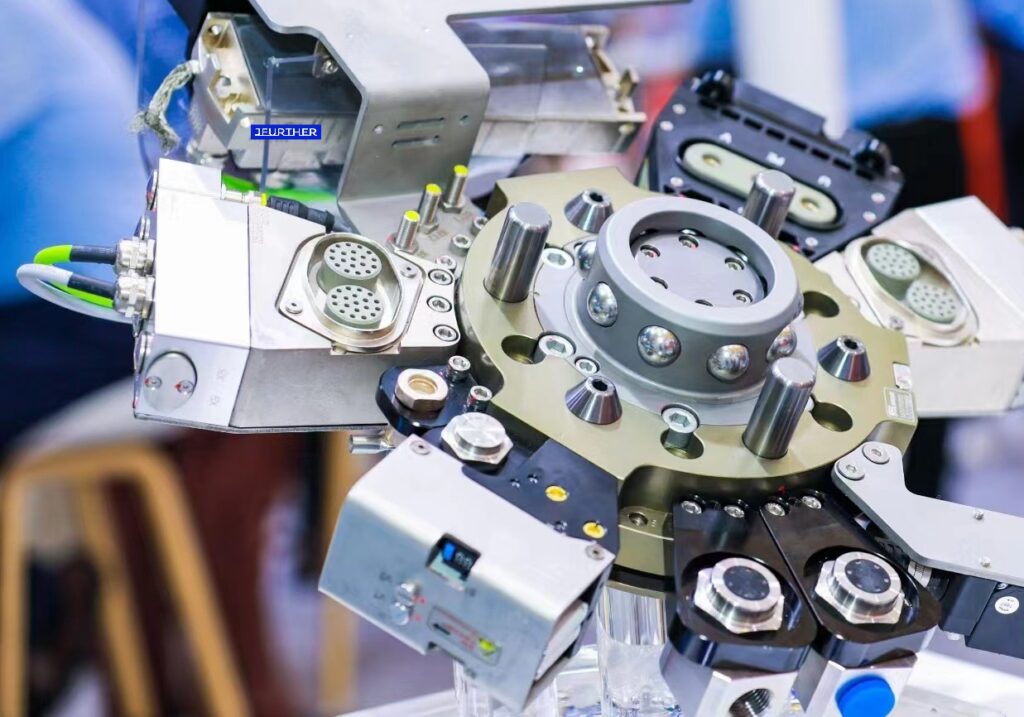

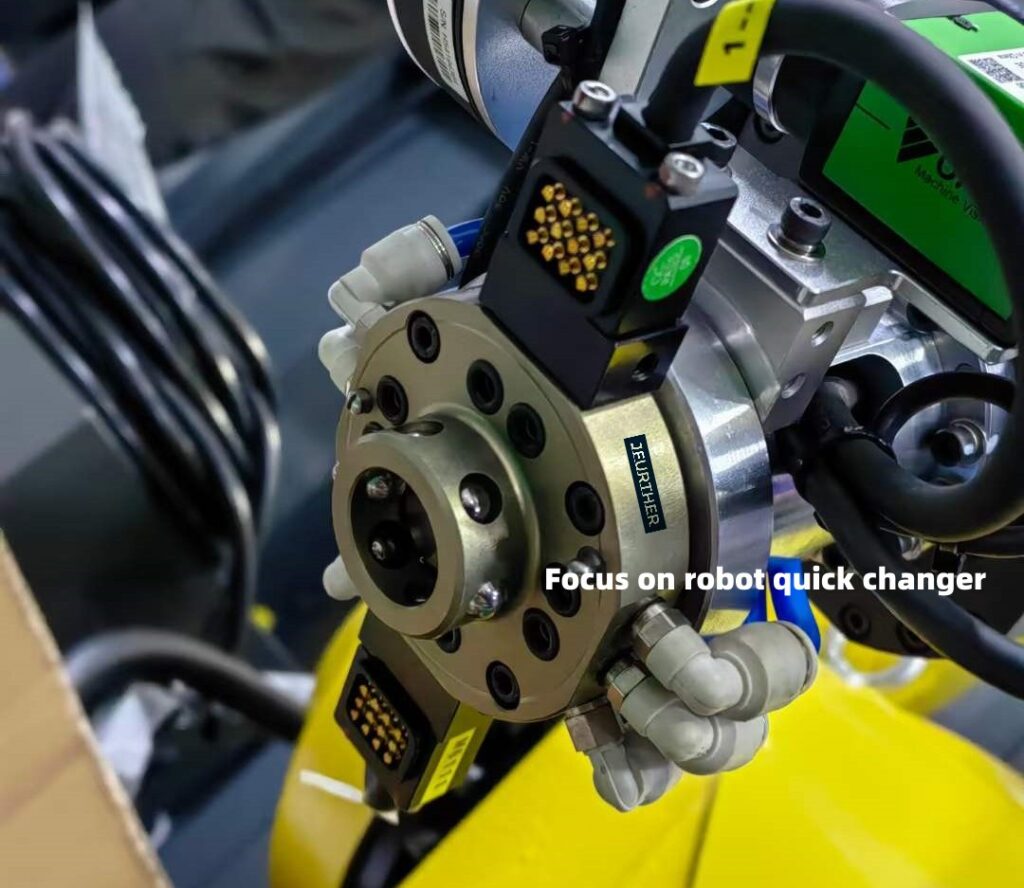

In today’s rapidly advancing industrial landscape, automation is at the forefront of improving efficiency, precision, and flexibility in manufacturing. One technology that’s driving this transformation is the Automatic Robot Tool Changer. This device allows industrial robots to quickly and seamlessly switch between different tools, enabling them to perform multiple tasks without manual intervention. The result? […]